Sour Gas Products

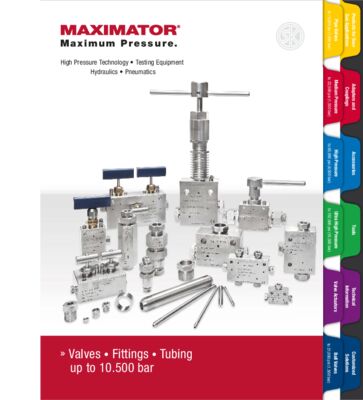

- Maximator offers a complete line of high pressure valves, fittings, tubing, check valves and line filters, adapters and couplings for standard oil field service where H2S is present.

- All high pressure valves and fittings use the high pressure style connection.

Maximator Sour Gas Valves are designed for oil and gas service where H2S is present and available rated to 22,500 psi (1,550 bar) or rated to 30,000 psi (2,070 bar). All pressure containing components are made from annealed 316 stainless steel material in compliance with NACE MR0175.

Maximator Sour Gas Valves are designed for oil and gas service where H2S is present and available rated to 22,500 psi (1,550 bar) or rated to 30,000 psi (2,070 bar). All pressure containing components are made from annealed 316 stainless steel material in compliance with NACE MR0175. Maximator Sour Gas Fittings are designed for oil and gas services where H2S is present.

Maximator Sour Gas Fittings are designed for oil and gas services where H2S is present. Maximator Sour Gas Tubing is designed for oil and gas services where H2S is present. All tubing is seamless annealed 316 stainless steel material in compliance with NACE MR0175.

Maximator Sour Gas Tubing is designed for oil and gas services where H2S is present. All tubing is seamless annealed 316 stainless steel material in compliance with NACE MR0175. Maximator offers a line of coned and threaded high pressure tube nipples in a variety of lengths for all standard tube sizes.

Maximator offers a line of coned and threaded high pressure tube nipples in a variety of lengths for all standard tube sizes. Maximator o-ring check valves provide high quality directional flow control and bubble tight shutoff for liquids and gases. These check valves are not to be used as a relief device. The opening pressure of the O-Ring Check Valves is approx. 10 psi (1.5 bar).

Maximator o-ring check valves provide high quality directional flow control and bubble tight shutoff for liquids and gases. These check valves are not to be used as a relief device. The opening pressure of the O-Ring Check Valves is approx. 10 psi (1.5 bar). Maximator dual-disc line filters are used to filter process fluids in high pressure systems. This design helps remove the large particles first through a coarse primary disc, which then allows a secondary disc to provide a smaller micron filtration.

Maximator dual-disc line filters are used to filter process fluids in high pressure systems. This design helps remove the large particles first through a coarse primary disc, which then allows a secondary disc to provide a smaller micron filtration. Maximator sour gas adapters and couplings are designed to join a variety of pressure connections where H2S ist present.

Maximator sour gas adapters and couplings are designed to join a variety of pressure connections where H2S ist present.