High Pressure Pumps

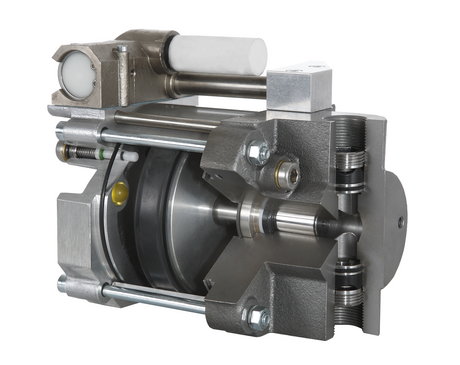

The compact, low-cost MAXIMATOR High-pressure Pumps are driven by air or noble gas pressures between 1 bar and 10 bar. There are numerous potential applications for MAXIMATOR Pumps in machine engineering, oil and gas industries, chemical and pharmaceutical industries, defence, mining and the construction industry as well as in aviation and aeronautics.